Gestra SRL63A

BRAND : Gestra

Description

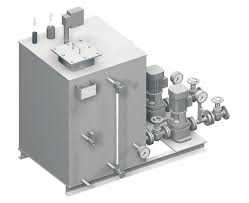

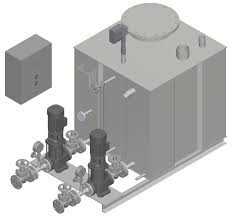

For the installation of low-level limiters of “high-integrity design” in measuring pots mounted outside of the boiler, it is imperative that the periodic purging of the connecting lines to the boiler be monitored properly. To achieve this, the connecting lines are shut off one after the other at defined intervals and the measuring pot is drained. The logic unit SRL 63 monitors compliance with the preset times and the sequence of valve operations; in addition, it bypasses the low-level limiter to ensure that the system is not shut down during purging. The logic unit for monitoring the purging cycle consists of a compact PLC, a safety time-lag relay and a coupling relay. The design complies with EN 50156

Function

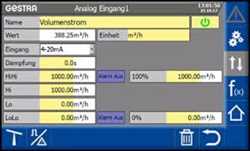

The logic unit monitors the following times:

? Interval time: This is the time interval at which, depending on the mode (24h / 72h operation), the connecting lines have to be purged.

? Standby period: The purging process must be initiated during this time. The standby period begins when the interval time has elapsed.

? Purging time: During this period, the purging process must be performed through actuation of the valves. Actuation of the valves is signalled by means of the limit switches; similarly, when the electrode of the low-level limiter is exposed, this is sensed through the output contact of the corresponding level switch. If a signal is not received within the purging time, the...

Details

Description

For the installation of low-level limiters of “high-integrity design” in measuring pots mounted outside of the boiler, it is imperative that the periodic purging of the connecting lines to the boiler be monitored properly. To achieve this, the connecting lines are shut off one after the other at defined intervals and the measuring pot is drained. The logic unit SRL 63 monitors compliance with the preset times and the sequence of valve operations; in addition, it bypasses the low-level limiter to ensure that the system is not shut down during purging. The logic unit for monitoring the purging cycle consists of a compact PLC, a safety time-lag relay and a coupling relay. The design complies with EN 50156

Function

The logic unit monitors the following times:

? Interval time: This is the time interval at which, depending on the mode (24h / 72h operation), the connecting lines have to be purged.

? Standby period: The purging process must be initiated during this time. The standby period begins when the interval time has elapsed.

? Purging time: During this period, the purging process

must be performed through actuation of the valves. Actuation of the valves is signalled by means of the limit

switches; similarly, when the electrode of the low-level

limiter is exposed, this is sensed through the output

contact of the corresponding level switch. If a signal is

not received within the purging time, the safety circuit is

opened. Since a low-level limiter may be bypassed for a

maximum of 5 minutes, monitoring of the purging time

is a safety-relevant function.