Gestra FPS11

BRAND : Gestra

Description

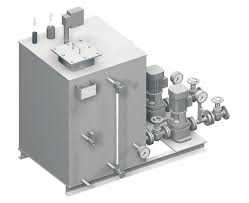

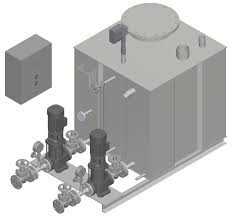

The steam-powered condensate-return unit FPS 11 uses booster steam to collect and pump condensate in level-dependent intervals . A special float valve controls the delivery intervals. This system does not require an electric condensate pump.

Function

The condensate enters the vessels through the inlet pipe 7, air venting is effected via the vent hole 8. As the condensate

level rises, the ball float 2 is lifted up. As soon as the maximum level is reached, a spring mechanism integrated in the float

valve 2 snaps over, closes the vent hole 8 and simultaneously opens the booster-steam valve 9. The booster-steam pressure closes the non-return valve 5 and pushes the condensate out through the outlet pipe 4. When the condensate level

reaches its lowest point, the spring mechanism closes the booster-steam valve 9 and simultaneously opens the vent hole 8.

Condensate can again flow into the vessel via the inlet pipe 7 until the next delivery cycle star

Details

Description

The steam-powered condensate-return unit FPS 11 uses booster steam to collect and pump condensate in level-dependent intervals . A special float valve controls the delivery intervals. This system does not require an electric condensate pump.

Function

The condensate enters the vessels through the inlet pipe 7, air venting is effected via the vent hole 8. As the condensate

level rises, the ball float 2 is lifted up. As soon as the maximum level is reached, a spring mechanism integrated in the float

valve 2 snaps over, closes the vent hole 8 and simultaneously opens the booster-steam valve 9. The booster-steam pressure closes the non-return valve 5 and pushes the condensate out through the outlet pipe 4. When the condensate level

reaches its lowest point, the spring mechanism closes the booster-steam valve 9 and simultaneously opens the vent hole 8.

Condensate can again flow into the vessel via the inlet pipe 7 until the next delivery cycle star