Gestra SRL6-40

BRAND : Gestra

Description

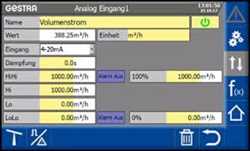

If the level electrode (high or low level limiter) is installed in an isolatable level pot outside the boiler, make sure that the level pot is drained and the connecting lines are rinsed at regular intervals. For this purpose the connecting lines must be shut off and opened at regular intervals and by opening and closing the drain valve the lines and the level pot will be rinsed. The logic unit SRL 6-40 is designed to be used in conjunction with control unit NRS 1-40.1 and NRS 1-40.2 to monitor the correct timing and sequence of valve operations. The equipment consists of a touch screen with integral PLC and I/O system. Its design is in accordance with EN 50156 and the data exchange is effected via CAN bus using the CANopen protocol.

Function

The logic unit monitors the following times and process sequences: ? Interval time: This is the time interval at which, depending on the operating mode (24h / 72h operation), the connecting lines have to be purged. ? Standby time: The purging process must be initiated during this time. The standby period begins when the interval time has elapsed. ? Purging time: During this period the valves must be operated so as to initiate the purging process. Operation of the valves and exposure of the LW level electrode is sensed and signalled by the limit switches. If a message is not received during the purging time, the safety circuit will be interrupted. The monitoring of the purgin...

Details

Description

If the level electrode (high or low level limiter) is installed in an isolatable level pot outside the boiler, make sure that the level pot is drained and the connecting lines are rinsed at regular intervals. For this purpose the connecting lines must be shut off and opened at regular intervals and by opening and closing the drain valve the lines and the level pot will be rinsed. The logic unit SRL 6-40 is designed to be used in conjunction with control unit NRS 1-40.1 and NRS 1-40.2 to monitor the correct timing and sequence of valve operations. The equipment consists of a touch screen with integral PLC and I/O system. Its design is in accordance with EN 50156 and the data exchange is effected via CAN bus using the CANopen protocol.

Function

The logic unit monitors the following times and process

sequences:

? Interval time: This is the time interval at which, depending on the operating mode (24h / 72h operation), the

connecting lines have to be purged.

? Standby time: The purging process must be initiated

during this time. The standby period begins when the

interval time has elapsed.

? Purging time: During this period the valves must be operated so as to initiate the purging process. Operation of the

valves and exposure of the LW level electrode is sensed

and signalled by the limit switches. If a message is not

received during the purging time, the safety circuit will

be interrupted. The monitoring of the purging time is a

safety-relevant function because a water level limiter may

be bypassed for a maximum of 5 minutes.