Gestra NRGS16-2

BRAND : Gestra

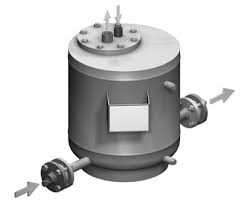

Compact System for Level Monitoring NRGS 11-2 NRGS 16-2

Description

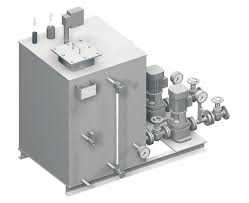

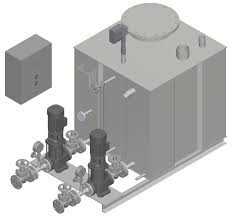

The NRGS 11-2, NRGS 16-2 is a compact-type system consisting of a level electrode with four tips and an integrated level switching controller. The compact system is used as water level controller / limiter, for instance in steam boilers, (pressurized) hot-water installations as well as condensate and feedwater collecting tanks.

Function

For the correct functioning of the equipment the water must

have a minimum conductivity of > 0.5 µS/cm at 25 °C.

The length of the individual electrode tips determines the

switchpoints for water level control and MIN level.

The equipment monitors the water level by sensing whether

the electrode tips are exposed or immersed and – by energizing or de-energizing the controller output contact – switches

the feedwater pump on or off. The LED for pump is illuminated

when the feedwater pump is switched on by the equipment.

When the water level falls below the low level, the two MIN

electrode tips are exposed and the equipment energises

the MIN output contacts after the de-energizing delay has

elapsed. The safety circuit for the heating will be opened and

the two MIN LED are illuminated.

A MIN alarm can be simulated by pressing the test button.

The heating will be switched off and interlocked. To reset the

interlock the MIN electrode tips must enter the water again

and the button “Reset” must be pushed.

Details

Compact System for Level Monitoring NRGS 11-2 NRGS 16-2

Description

The NRGS 11-2, NRGS 16-2 is a compact-type system consisting of a level electrode with four tips and an integrated level switching controller. The compact system is used as water level controller / limiter, for instance in steam boilers, (pressurized) hot-water installations as well as condensate and feedwater collecting tanks.

Function

For the correct functioning of the equipment the water must

have a minimum conductivity of > 0.5 µS/cm at 25 °C.

The length of the individual electrode tips determines the

switchpoints for water level control and MIN level.

The equipment monitors the water level by sensing whether

the electrode tips are exposed or immersed and – by energizing or de-energizing the controller output contact – switches

the feedwater pump on or off. The LED for pump is illuminated

when the feedwater pump is switched on by the equipment.

When the water level falls below the low level, the two MIN

electrode tips are exposed and the equipment energises

the MIN output contacts after the de-energizing delay has

elapsed. The safety circuit for the heating will be opened and

the two MIN LED are illuminated.

A MIN alarm can be simulated by pressing the test button.

The heating will be switched off and interlocked. To reset the

interlock the MIN electrode tips must enter the water again

and the button “Reset” must be pushed.