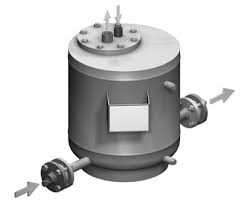

Gestra NRG16-41.1

BRAND : Gestra

System Description

The level electrode operation is based on the conductive measuring principle. The NRG 1...-41.1 is designed for signalling the max. liquid level in electrically conductive liquids. n One liquid level with one switchpoint The NRG 1...-41.1 is to be used in conjunction with the multi-purposed control equipment NRS 1-40.1. The level data are transferred from the electrode NRG 1...-41.1 to the control unit via a CAN bus using the CANopen protocol.

Function

The conductivity of the liquid is used to signal the liquid level. Some liquids are conductive, which means that they allow an electric current to flow through them. For the safe functioning of this device a minimum conductivity of the liquid to be measured is required. The conductivity measurement method can detect two conditions: electrode rod submerged or exposed, meaning switchpoint reached (or exceeded) or not yet reached. Before installation, the length of the electrode rod must be cut to the required switching level, e. g. for “Pump off” or “Control valve closed” or, in case of economiser and air heaters that are installed close to the steam-generating unit and exposed to a risk, “Firing/Burner off”. An additional electrode fully integrated in the system automatically monitors the electrical resistance path between earth and measuring electrode. As soon as the actual value falls below the admissible resistance value the protection circuit is interrupted...

Details

System Description

The level electrode operation is based on the conductive measuring principle. The NRG 1...-41.1 is designed for signalling the max. liquid level in electrically conductive liquids. n One liquid level with one switchpoint The NRG 1...-41.1 is to be used in conjunction with the multi-purposed control equipment NRS 1-40.1. The level data are transferred from the electrode NRG 1...-41.1 to the control unit via a CAN bus using the CANopen protocol.

Function

The conductivity of the liquid is used to signal the liquid

level. Some liquids are conductive, which means that they

allow an electric current to flow through them. For the safe

functioning of this device a minimum conductivity of the liquid

to be measured is required.

The conductivity measurement method can detect two

conditions: electrode rod submerged or exposed, meaning

switchpoint reached (or exceeded) or not yet reached. Before

installation, the length of the electrode rod must be cut to

the required switching level, e. g. for “Pump off” or “Control

valve closed” or, in case of economiser and air heaters that

are installed close to the steam-generating unit and exposed

to a risk, “Firing/Burner off”.

An additional electrode fully integrated in the system automatically monitors the electrical resistance path between earth

and measuring electrode. As soon as the actual value falls

below the admissible resistance value the protection circuit is

interrupted and cuts off the pump or heat supply to the boiler.

At regular intervals the level electrode NRG 1...-41.1 sends

a data telegram to the switching controller NRS 1-40.1. The

data are transferred via a CAN bus to DIN ISO 11898 using

the CANopen protocol.