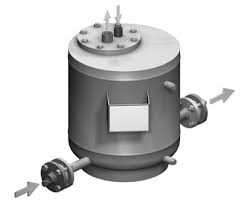

Gestra NDR-SW

BRAND : Gestra

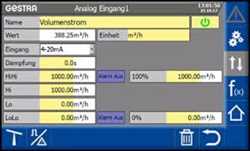

Technical Data Service pressure 0.5 barg Service temperature 111 °C Capacity 0.5 m³/h up to 70 m³/h > 70 m³/h on request

Description

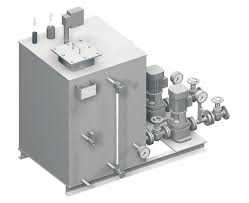

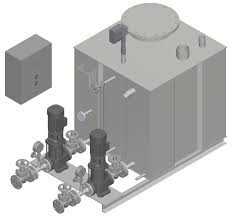

The feedwater deaerating plant, consisting of the feedwater

tank SW and the deaerator dome NDR, removes dissolved

gases such as oxygen, carbon dioxide and other non-condensable gases from boiler feedwater and make-up water.

For the operation of steam boilers with high thermal load

on the heating surfaces boiler feedwater that is treated and

conditioned according to TRD 611, EN 12952 part 12 or

EN 12953 part 10 must be used.

The boiler feedwater must be free of hardening constituents

in order to prevent the formation of scale on the boiler heating surfaces. The presence of dissolved oxygen and carbon

dioxide causes severe corrosion of metal boiler parts. The

feedwater deaerating plant is custom designed for each

application and meets essential thermodynamic requirements

to achieve optimal performance.

Details

Technical Data Service pressure 0.5 barg Service temperature 111 °C Capacity 0.5 m³/h up to 70 m³/h > 70 m³/h on request

Description

The feedwater deaerating plant, consisting of the feedwater

tank SW and the deaerator dome NDR, removes dissolved

gases such as oxygen, carbon dioxide and other non-condensable gases from boiler feedwater and make-up water.

For the operation of steam boilers with high thermal load

on the heating surfaces boiler feedwater that is treated and

conditioned according to TRD 611, EN 12952 part 12 or

EN 12953 part 10 must be used.

The boiler feedwater must be free of hardening constituents

in order to prevent the formation of scale on the boiler heating surfaces. The presence of dissolved oxygen and carbon

dioxide causes severe corrosion of metal boiler parts. The

feedwater deaerating plant is custom designed for each

application and meets essential thermodynamic requirements

to achieve optimal performance.