Gestra LRGS15-1

BRAND : Gestra

Description

The conductivity switch LRGS 15-1 is a compact system consisting of a conductivity monitoring electrode and a conductivity switch integrated in the terminal box. The LRGS 15-1 is used as limit switch and continuous blowdown controller in steam boilers.

Technical Data

Service pressure PN25: 25 barg at 224 °C Mechanical connection Screwed ¾", ISO 228-1 Screwed ¾" NPT (optional) Materials Screw-in electrode body: 1.4571, X6CrNiMoTi17-12-2 or 1.4404, A 479 316 L (for NPT thread) Measuring electrode: 1.4571, X6CrNiMoTi17-12-2 Electrode rod insulation: PTFE Terminal box: Polycarbonate Measuring length & length of installation 200, 300, 400, 500, 600, 800, 1000 mm Input 1 Input for resistance thermometer, e. g. TRG 5-53, measuring insert Pt 100 Measuring range 100 to 10000 µS/cm at 25 °C or 50 to 5000 ppm at 25 °C Setpoint Adjustable between 100 and 10000 µS/cm or 50 to 5000 ppm MAX limit Adjustable between 100 and 10000 µS/cm or 50 to 5000 ppm Switching hysteresis Controller output: –10 % of the adjusted setpoint MAX limit: –3 % of the adjusted MAX limit

Temperature coefficient Tk (if a resistance thermometer Pt 100 is connected) 1.6 – 3.0 % per °C, adjustable in steps of 0.1 Supply voltages 230 V, +10 / –15 %, 50-60 Hz 115 V, +10 / –15 %, 50-60 Hz (optional) Power consumption 5 VA Fuse External slow-blow fuse 63 mA at 230 V External slow-blow fuse 125 mA at 115 V Output 3 Volt-free relay co...

Details

Description

The conductivity switch LRGS 15-1 is a compact system consisting of a conductivity monitoring electrode and a conductivity switch integrated in the terminal box. The LRGS 15-1 is used as limit switch and continuous blowdown controller in steam boilers.

Technical Data

Service pressure PN25: 25 barg at 224 °C Mechanical connection Screwed ¾", ISO 228-1 Screwed ¾" NPT (optional) Materials Screw-in electrode body: 1.4571, X6CrNiMoTi17-12-2 or 1.4404, A 479 316 L (for NPT thread) Measuring electrode: 1.4571, X6CrNiMoTi17-12-2 Electrode rod insulation: PTFE Terminal box: Polycarbonate Measuring length & length of installation 200, 300, 400, 500, 600, 800, 1000 mm Input 1 Input for resistance thermometer, e. g. TRG 5-53, measuring insert Pt 100 Measuring range 100 to 10000 µS/cm at 25 °C or 50 to 5000 ppm at 25 °C Setpoint Adjustable between 100 and 10000 µS/cm or 50 to 5000 ppm MAX limit Adjustable between 100 and 10000 µS/cm or 50 to 5000 ppm Switching hysteresis Controller output: –10 % of the adjusted setpoint MAX limit: –3 % of the adjusted MAX limit

Temperature coefficient Tk

(if a resistance thermometer Pt 100 is connected)

1.6 – 3.0 % per °C, adjustable in steps of 0.1

Supply voltages

230 V, +10 / –15 %, 50-60 Hz

115 V, +10 / –15 %, 50-60 Hz (optional)

Power consumption

5 VA

Fuse

External slow-blow fuse 63 mA at 230 V

External slow-blow fuse 125 mA at 115 V

Output

3 Volt-free relay contacts

5 A 230 V AC / 30 V DC cos ? = 1 (IEC 61810)

Provide contactor with inference suppressor

(RC combination).

Contact material: AgNi 0.15

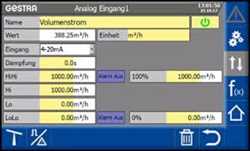

Indicators and adjustors

1 Four-digit, seven-segment indicator, red, for showing the

actual value (X) / setpoint (W) and status & malfunction

messages

2 Amber LEDs for indicating the actual value (X) /

setpoint (W)

1 Red LED for indicating the MAX limit

2 Green LEDs for indicating “Valve OPEN / CLOSED”

4 Pushbuttons for parameter settings

Cable entry / Electrical connection

Cable glands with integrated cable clamp,

3 x M 16 x 1.5

1 Four-pole screw-type terminal strip for mains connection

1 Three-pole screw-type terminal strip for connecting the

continuous blowdown valve

1 Three-pole screw-type terminal strip for MAX limit

The terminal strips can be detached;

conductor size 1.5 mm2

4 Terminal lugs for connecting the resistance thermometer

Protection

IP 65 to DIN EN 60529

Protection class

2 (protective insulation)

Weight

Approx. 1.5 kg

Ambient temperature

when system is switched on: 0 ° ... 70 °C,

during operation: -10 ... 70 °C

Transport temperature

–20 ... +80 °C (< 100 hours), defrosting time of the de-energized equipment before it can be put into operation: 24 hours.

Storage temperature

–20 ... +70 °C, defrosting time of the de-energized equipment

before it can be put into operation: 24 hours.

Relative humidity

max. 95%, no moisture condensation

Site altitude

max. 2000 m