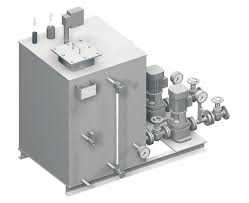

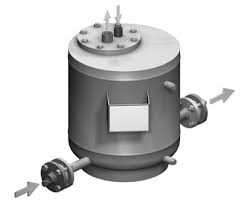

Gestra KH Steam-Powered Condensate-Return Unit

BRAND : Gestra

Description

The condensate flows into the upright cylindrical tank, displacing the air through a solenoid valve. The tank is equipped with the compact level system type NRGS 11-1 / NRGS 16-1. As soon as the water level reaches the upper electrode tip the solenoid valve in the vent line is closed and simultaneously the solenoid valve in the booster-steam line (introduced from above into the tank) is opened. The flowing steam pushes the condensate via the condensate main into the condensate tank. The condensate level sinks and when the lower electrode tip emerges, the solenoid valve in the booster-steam line is closed and the solenoid valve in the vent line opened. The cycle repeats itself. Before entering the condensate-return unit the condensate is collected in a condensate header to be provided on site. This condensate header should be equipped with a vent. Condensate inlet and outlet are provided with GESTRA DISCO non-return valves type RK. The condensate-return unit is equipped with a pressure-gauge and the booster-steam line with a stop valve with characterized valve cone which permits the adjustment of the booster-steam pressure in accordance with the length of the condensate discharge line and the prevailing back pressure. As the condensate-return unit operates without a float it is unaffected by waterhammer. Continuous drainage of the booster-steam line upstream of the solenoid valve is ensured by a GESTRA steam trap. The steam t...

Details

Description

The condensate flows into the upright cylindrical tank,

displacing the air through a solenoid valve.

The tank is equipped with the compact level system type NRGS

11-1 / NRGS 16-1. As soon as the water level reaches the

upper electrode tip the solenoid valve in the vent line is closed

and simultaneously the solenoid valve in the booster-steam

line (introduced from above into the tank) is opened. The

flowing steam pushes the condensate via the condensate

main into the condensate tank. The condensate level sinks

and when the lower electrode tip emerges, the solenoid valve

in the booster-steam line is closed and the solenoid valve in

the vent line opened. The cycle repeats itself.

Before entering the condensate-return unit the condensate

is collected in a condensate header to be provided on site.

This condensate header should be equipped with a vent.

Condensate inlet and outlet are provided with GESTRA DISCO

non-return valves type RK. The condensate-return unit is

equipped with a pressure-gauge and the booster-steam line

with a stop valve with characterized valve cone which permits

the adjustment of the booster-steam pressure in accordance

with the length of the condensate discharge line and the

prevailing back pressure.

As the condensate-return unit operates without a float it is

unaffected by waterhammer.

Continuous drainage of the booster-steam line upstream

of the solenoid valve is ensured by a GESTRA steam trap.

The steam traps, non-return valves and compact systems

are described in separate data sheets.