Gestra KDS13

BRAND : Gestra

Description

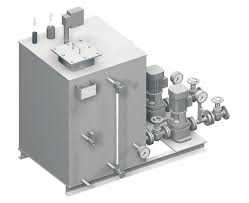

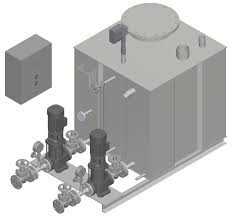

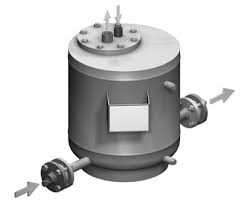

The desuperheater KD...13 consists of a vessel with builtin nozzle arrangement for injecting and cooling superheated steam in a water bath. The KD...13 is suitable for all applications where an effective conversion of superheated steam into saturated steam is required. The desuperheater is available for different operating loads as horizontal design KDL 13 or vertical design KDS 13. The KD...13 is custom designed for each application and meets essential thermodynamic requirements to achieve optimal performance.

Function

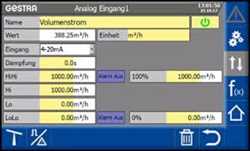

Superheated steam at a max. temperature of 400 °C is introduced into a controlled system and injected through a nozzle into a water bath where it is cooled down to the temperature of the saturated steam. In passing through the water the superheat energy of the steam is given up to the cooling water, with some of the cooling water being evaporized and entrained as saturated steam. The steam content after the cooling process is 98 %. The desuperheater features an integral water separator that prevents the cooling water from being carried along into the steam line during peak loads. The level electrode NRG ... or NRGT ... detects the cooling water level and an electronic control unit ensures that the evaporized cooling water is replaced by make-up water. The cooling water at the required upstream pressure is fed into the lower part of the desuperheater via a control valve or a solenoid valve. If the temper...

Details

Description

The desuperheater KD...13 consists of a vessel with builtin nozzle arrangement for injecting and cooling superheated steam in a water bath. The KD...13 is suitable for all applications where an effective conversion of superheated steam into saturated steam is required. The desuperheater is available for different operating loads as horizontal design KDL 13 or vertical design KDS 13. The KD...13 is custom designed for each application and meets essential thermodynamic requirements to achieve optimal performance.

Function

Superheated steam at a max. temperature of 400 °C is introduced into a controlled system and injected through a nozzle

into a water bath where it is cooled down to the temperature of

the saturated steam. In passing through the water the superheat energy of the steam is given up to the cooling water, with

some of the cooling water being evaporized and entrained as

saturated steam. The steam content after the cooling process

is 98 %. The desuperheater features an integral water separator that prevents the cooling water from being carried along

into the steam line during peak loads. The level electrode

NRG ... or NRGT ... detects the cooling water level and an

electronic control unit ensures that the evaporized cooling

water is replaced by make-up water. The cooling water

at the required upstream pressure is fed into the lower

part of the desuperheater via a control valve or a solenoid

valve. If the temperature of the steam is very high the cooling

water must be heated up. The water-bath desuperheater is

the only steam cooling system that supplies saturated steam

over a control range of 0 – 100 %.