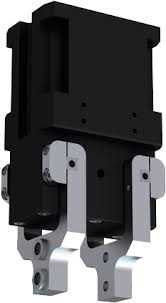

Zimmer Group CSR Series Crash Protection

BRAND : Zimmer Group

By controlling the air pressure, you can optimally match the sensitivity to your application

If there is a collision, the integrated sensor gives a signal to the control system to trigger an emergency stop.

We forgo an automatic return and ensure that the operator inspects the machine and the reason for the emergency stop

Details

By controlling the air pressure, you can optimally match the sensitivity to your application

If there is a collision, the integrated sensor gives a signal to the control system to trigger an emergency stop.

We forgo an automatic return and ensure that the operator inspects the machine and the reason for the emergency stop

INSTALLATION SIZE: CSR50

| Order-No. | Connecting flange according EN ISO 9409-1 | Installation Height | Recommended handling weight | |

|---|---|---|---|---|

| CSR50 | TK 50 | 71 [mm] | 6 [kg] |

INSTALLATION SIZE: CSR63

| Order-No. | Connecting flange according EN ISO 9409-1 | Installation Height | Recommended handling weight | |

|---|---|---|---|---|

| CSR63 | TK 63 | 78 [mm] | 12 [kg] |

INSTALLATION SIZE: CSR80

| Order-No. | Connecting flange according EN ISO 9409-1 | Installation Height | Recommended handling weight | |

|---|---|---|---|---|

| CSR80 | TK 80 | 78.5 [mm] | 35 [kg] |

INSTALLATION SIZE: CSR100

| Order-No. | Connecting flange according EN ISO 9409-1 | Installation Height | Recommended handling weight | |

|---|---|---|---|---|

| CSR100 | TK 100 | 97.5 [mm] | 60 [kg] |

INSTALLATION SIZE: CSR125

| Order-No. | Connecting flange according EN ISO 9409-1 | Installation Height | Recommended handling weight | |

|---|---|---|---|---|

| CSR125 | TK 125 | 136 [mm] | 100 [kg] |

INSTALLATION SIZE: CSR160

| Order-No. | Connecting flange according EN ISO 9409-1 | Installation Height | Recommended handling weight | |

|---|---|---|---|---|

| CSR160 | TK 160 | 161 [mm] | 150 [kg] |

|