Details

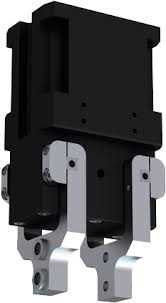

"THE ELECTRIC COMPACT ONE"

- Largest stroke in small installation space

Do you require a large stroke, due to the fact that you are operating either a form fit gripper or a large range of parts but the installation space and the load capacity of your application is limited? Then this gripper is perfect for you! - Adjustable gripping force

Using pressures that are too high can damage your workpieces! You can optimally adjust the gripping force to your workpiece by means of the integrated potentiometer or over the control system via IO-Link. - The simplest activation

It is your choice whether you want to control the gripper by means of I/O ports—like a valve—or if you prefer the version with IO-Link. Both have this in common: they are easy to integrate into your control system.

| Order-No. | Integrated sensing | ZIM_ICON_AUO_IOLINK | |

|---|---|---|---|

| GEP2006IL-00-A | Ja | Ja | |

| GEP2006IO-00-A | |||

| GEP2006IO-05-A | Ja |

INSTALLATION SIZE: GEP2010

| Order-No. | Integrated sensing | ZIM_ICON_AUO_IOLINK | |

|---|---|---|---|

| GEP2010IL-00-A | Ja | Ja | |

| GEP2010IO-00-A | |||

| GEP2010IO-05-A | Ja |

INSTALLATION SIZE: GEP2013

| Order-No. | Integrated sensing | ZIM_ICON_AUO_IOLINK | |

|---|---|---|---|

| GEP2013IL-00-A | Ja | Ja | |

| GEP2013IO-00-A | |||

| GEP2013IO-05-A | Ja |

INSTALLATION SIZE: GEP2016

| Order-No. | Integrated sensing | ZIM_ICON_AUO_IOLINK | |

|---|---|---|---|

| GEP2016IL-00-A | Ja | Ja | |

| GEP2016IO-00-A | |||

| GEP2016IO-05-A |

|