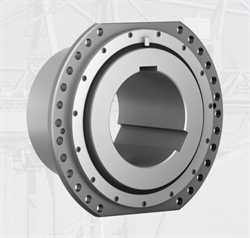

Ringfeder RfN 4161 Standart Series Shrink Disc

BRAND : Ringfeder

Standard series – this range is the most popular, being used in most applications. High transmission values are possible and by varying the screw tightening torque the Shrink disc can be adapted to the design specification.

Characteristics

Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapere...

Details

Standard series – this range is the most popular, being used in most applications. High transmission values are possible and by varying the screw tightening torque the Shrink disc can be adapted to the design specification.

Characteristics

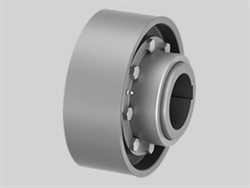

Shrink discs are the modern method for creating a mechanical shrink fit. The shrink disc consists of either one or two thrust rings with tapered bores and a mating tapered inner ring. By tightening locking screws the thrust rings are drawn together compressing the inner ring and applying pressure to the outside of the hub clamping it to the shaft. Being positioned around the hub there is only one interface transmitting the loads giving the shrink disc method distinct advantages such as offering the possibility of very concentric and well balanced connections that are suited to high speed applications. Traditional shrink fits require complicated calculations, close machining tolerances and fine surface finishes, they also need considerable effort with mounting and removal. The shrink disc connection has none of these disadvantages and is better than any of the other usual connection methods with regard to fatigue strength under alternating torsional stress.

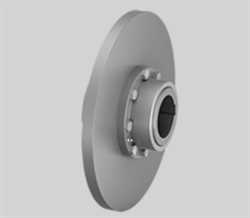

- Unlimited range of applications – RINGFEDER® Shrink Disc connections are suitable for securing all types of hubs onto shafts and axles. Replacing traditional shrink fits, keys and polygon connections, splined shafts etc. So cog wheels and sprockets, levers, lifters, cam discs, pulleys or brake discs, balance wheels, couplings, slip on gear mechanisms, flanges, pulley wheels and rotors can be attached absolutely reliable.

- Standard design – for high transmission values.

- Compensation of small tolerance errors – please contact our engineers.

- Maximum reliability – suitable for static, dynamic and impact loads.

- Slitted inner ring – low forces and pressures on hub and shaft.

- Simplified manufacture – only plain shaft and bore diameters with easily achieved surface finish and tolerances are required.

- Easy replacement – The RINGFEDER® shrink disc is free from any form fit.

- Easy mounting – no steps, keyways, splines are required, therefore hubs can be located and locked at any point or angle on the shaft. RINGFEDER® Shrink Discs use standard screws tightened with standard tools. No additional machining or fitting work is required.

- Short installation time - cost savings particularly in serial production.

- Easy removal – after loosening the locking screws, the RINGFEDER® Shrink Disc will self release and the hub will move freely on the shaft.

- Low

susceptibility to contamination – when the locking screws are

tightened the functional contact surfaces are pressed firmly together and

prevent the ingress of dirt and moisture.

Surface finishes

For shaft diameter dw:

Peak-to-valley height Ra ? 3,2 ?m.