Ringfeder GWE 5104 Elastomer Jaw Coupling

BRAND : Ringfeder

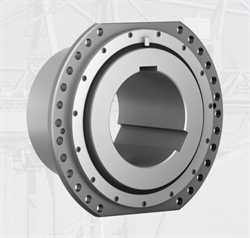

Self-aligning coupling with clamping hubs and dual slits

Jaw couplings in the series RINGFEDER®...

Details

Self-aligning coupling with clamping hubs and dual slits

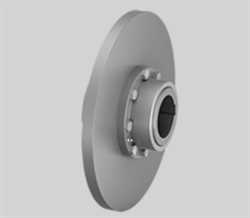

Jaw couplings in the series RINGFEDER® GWE 5104, with clamp hubs and a high level of international standardisation. Up to size 19 it comprises two axially (single-)slit and from size 24 two axially and radially (double-)slit clamp hubs with high concentricity and an elastomer spider that can be supplied in different levels of Shore hardness. The shaft tolerance should lie within the ?t tolerance ‘g6’ to ‘h7’.

The coupling is available with elastomer spiders in different Shore hardness levels and impresses with its special damping properties.

Characteristics

Backlash-free Elastomer Jaw Couplings

RINGFEDER® GWE

Backlash-free RINGFEDER® GWE jaw couplings are used in engineering where high positioning precision requires vibration damping in greatly accelerated processes and the use of plug-in coupling solutions is preferred.

Advantages

- Backlash-free, through pre-stressing

- Pluggable

- Vibration damping

- Torques from 0,5 – 650 Nm

- Compensation of radial, axial and angular misalignment

- Electrically isolating

Applications

- Encoder

- Precision drives

- Feed drives

- Grinding and milling spindles

- Machine tools

- Packing machines

- Robotics

- Transfer lines

- Multi-spindle heads

- Wood processing equipment

- Textile machinery

- Conveying equipment

- Linear motion

- Measuring equipment and control technology

- Test rigs

Technical description

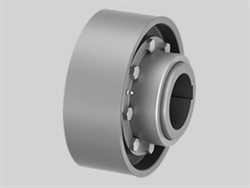

Every hub on the RINGFEDER® GWE jaw coupling has concave jaws on its face. The function of the coupling to transmit torque and damp impact that occurs, as well as balancing out unavoidable mis- alignments, is enabled through the joining of two hubs and the ?lling of the created free space with an elastic sprocket. The GWE jaw couplings are backlash-free in order to also achieve a high level of positioning precision in reverse operation. The coupling is backlash-free as a result of the pressure pre-tensioning of the individual buffers in the elastomer sprocket. The different Shore hardness levels, which correlate to the torsional stiffness, mean that it is possible to optimise the entire drive line from the point of view of rotary oscillation. Detailed information is included in the technical data for the sprockets.

Characteristics GWE 5104

- Low mass through aluminium hubs

- Optimisation of the vibration damping through different elastomer spider hardness levels

- As standard with red elastomer spider. Up to size 55 in 98 Shore A and from size 65 in 95 Shore A

- Installation space in accordance with the known market standard

- Puncture-proof and electrically insulating

- Coupling hubs optionally with keyways in accordance with DIN 6885-1