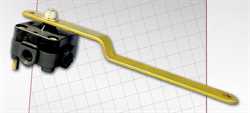

Barksdale 450E (B?T) Series Intelligent Proof Transmitter

BRAND : Barksdale

Barksdale Intelligent Transmitters (BiT), Series 450E and H450E are BiT's Intrinsically Safe models. Barksdale has been manufacturing explosion proof transmitters for many years allowing their use in Class I Div 1 or Zone 0, 1 hazardous location. So why introduce an Intrinsically Safe (I.S.) model? Explosion proof wiring requires metal conduit and special explosion proof sealing glands and junction boxes which are not practical for equipment that needs to be quickly rigged or broken down to modular sections to transport on roads to the next location such as Drilling, Frac or other mobile equipment. I.S. protection concept allows use in the same hazardous areas as explosion proof only with the same flexible cables and electrical connections used in ordinary locations including industrial and military style connectors used on our BiT 450 ordinary location models. Maintenance of systems is greatly simplified with quick electrical disconnects and no expensive explosion proof boxes that are susceptible to scratches on sealing flame path surfaces during maintenance...

Details

Barksdale Intelligent Transmitters (BiT), Series 450E and H450E are BiT's Intrinsically Safe models. Barksdale has been manufacturing explosion proof transmitters for many years allowing their use in Class I Div 1 or Zone 0, 1 hazardous location. So why introduce an Intrinsically Safe (I.S.) model? Explosion proof wiring requires metal conduit and special explosion proof sealing glands and junction boxes which are not practical for equipment that needs to be quickly rigged or broken down to modular sections to transport on roads to the next location such as Drilling, Frac or other mobile equipment. I.S. protection concept allows use in the same hazardous areas as explosion proof only with the same flexible cables and electrical connections used in ordinary locations including industrial and military style connectors used on our BiT 450 ordinary location models. Maintenance of systems is greatly simplified with quick electrical disconnects and no expensive explosion proof boxes that are susceptible to scratches on sealing flame path surfaces during maintenance. Barksdale’s new intrinsically safe models also include advanced Thin-Film and HART technology providing all of the advantages of our other models including high accuracy and long term stability.

General Specifications*

| Accuracy (LH & R): at 75°F, Typical | ±0.10% of Calibrated FSO (Option [–A1]) ±0.25% of Calibrated FSO (Standard) ±0.50% of Calibrated FSO (Vacuum only [-23]) |

| Temperature Shift: | Zero & Span: 0.0125% Per °F over the compensated temperature range |

| Long Term Stability:closure rating: | ±0.2% FSO /year of calibration curve |

| Typical Life Cycle: | 100 million cycles |

| Proof Pressure: | 2X range for up to 7,500 psi models 1.5X range for 7,500 - 30,000 psi models |

| Input: | Excitation voltage: 9 to 30 VDC |

| Supply Current: | 20mA max. |

| Output: H455E: 455E: | Output: 4–20 mA with HART® Protocol Full Scale Output: 20 mA ±1% Zero output: 4 mA ±1% Output: 4–20 mA Full Scale Output: 20 mA ±1% Zero output: 4 mA ± 1% |

| Dynamic Response Time: | |

| Enclosure: | All welded 300 series stainless steel. IP66 & IP67 and NEMA 4X rated. 316 Stainless Steel (optional) |

| Wetted Parts: Sensor: Fitting: | 17-4 PH Stainless steel (more than 10k psi) 316L Stainless steel (up to 10k psi) Inconel (optional: up to 10k psi) 17-4 PH Stainless steel for -UL option (10k psi) 17-4 PH Stainless steel (all ranges) 316L Stainless steel and 718 Inconel (optional: up to 10k psi) |

| Media General: Corrosive and Acidic: (up to 10,000 psi) | Gas, vapor, liquid and viscous fluids [-Z17] 718 Inconel wetted material, NACE [-NC], and 316L stainless steel, NACE [-SS] |

| Pressure Connection: | 13 available options. Refer to product configurator for available connections and ranges. |

| Electrical Connection: | 10 available electrical connections such as M12, Bendix, DIN, conduit, gland and etc. Option for free leads from conduit or gland electrical connection includes two signal leads plus ground lead consisting of 18AWG halogen free type, 80” (2m) long or optional jacketed cable exiting 1/2 NPT or M20 conduit or gland connections. |

| Temperature Ranges: Operating (Ambient): Compensated: Media: Storage: | -40 to +176 °F (-40 to +80 °C) 0 to +165 °F (-18 to +74 °C) -40 to +176 °F (-40 to +80 °C) -40 to +185 °F (-40 to +85 °C) |

| Vibration: | 10 g’s, 10-500 Hz, MIL-STD 202, Method 204, Cond. A |

| Shock: | 50 g’s, 11 mS, MIL-STD 202 Method 213, Cond. G. |

| Approvals: CSA CSA ATEX/IECEx | cCSAus Ordinary Locations cCSAus Intrinsic Safety for Hazardous Locations Class I, Div. 1, Groups A, B, C & D Class II, Div. 1, Groups E, F & G Ex ia IIC T4 Ga Ex ia IIIC T135°C Da Class 1 Zone 0, AEx ia IIC T4 Ga Zone 20 AEx ia IIIC T135°C Da Factory sealed IP66 & IP67 and NEMA 4X enclosure CE 0081 Ex II 1 G D Ex ia IIC T4 Ga Ex ia IIIC T135°C Da, IP66 & IP67 -40 °C ? Tamb ? +80 °C CML 19 ATEX 2240X IECEx CML 19.0066X |

| HART® Protocol: Turndown Ratio: Analog Output Calibration: Sensor Trim: Diagnostics: | HART® 7.6 10:1 (Full scale output rangeability) Adjustable zero and span of 4-20mA. Full scale range must be ? (calibrated span / 10) Sensor zero and full scale trim Transmitter failure indicated by off-scale analog signals to alarm the user See HART Installation and Operation Manual 272438 for detailed information |

| Compliances: | CE, NACE (316L SS or 718 Inconel wetted material) |

| Electromagnetic Capability (EMC) IEC/EN 55011: IEC/EN 61000-4-2: IEC/EN 61000-4-3: IEC/EN 61000-4-4: IEC/EN 61000-4-5: IEC/EN 61000-4-6: | Emission & radiated emission for class A limits Electrostatic discharge (ESD) test - contact discharge +/-4 kV, Air discharge +/-8 kV Radiated RF, EM field immunity 80mhz-1ghz, 3v/M EFT (Burst) Test, +/-2 kV Surge Test, +/-1kV on lines, +/-2kV between line and earth ground RF Immunity, 150 kHz – 80 MHz, 3V |

| Weight: | 16 Ounces (453 grams) |

| Warranty: | 1 year warranty |

| Installation: | Intrinsic Safety Installation for Hazardous Locations: Install per Barksdale Control Drawing 272471 |