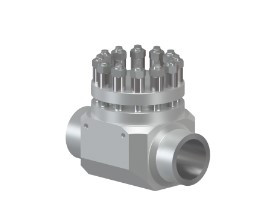

Armatury Z16 Lift check valve

BRAND : Armatury

Application Lift check valves are self-acting valves

preventing the back flow of the fluid. It is used especially in power

engineering, chemical industry as well as other industries depending on

material selection. Lift check valves are not shut-off valves. Working medium

water steam gas sea water other fluids Technical description The body is a

forged or a cast depending on nominal size and nominal pressure. The disc is inserted

into the valve body through the body-cover joint. Both the disc and the seat

are hard faced and the disc is pressed into seat by a spring. Operation

self-acting operation Testing Valves are subject to shell strength test, shell

tightness test, seat tightness test and functionality test according to EN

12266 with water as a standard. If required, other tests may be performed as

well. Connection to the piping flanged ends acc. to EN 1092-1, ISO 7005-1, GOST

12815-80 welded ends acc. to EN 12627 Installation Lift check valves may be

installed in any position. The flow direction shall correspond to the arrow on

the valve body.

Details

Application Lift check valves are self-acting valves

preventing the back flow of the fluid. It is used especially in power

engineering, chemical industry as well as other industries depending on

material selection. Lift check valves are not shut-off valves. Working medium

water steam gas sea water other fluids Technical description The body is a

forged or a cast depending on nominal size and nominal pressure. The disc is inserted

into the valve body through the body-cover joint. Both the disc and the seat

are hard faced and the disc is pressed into seat by a spring. Operation

self-acting operation Testing Valves are subject to shell strength test, shell

tightness test, seat tightness test and functionality test according to EN

12266 with water as a standard. If required, other tests may be performed as

well. Connection to the piping flanged ends acc. to EN 1092-1, ISO 7005-1, GOST

12815-80 welded ends acc. to EN 12627 Installation Lift check valves may be

installed in any position. The flow direction shall correspond to the arrow on

the valve body.