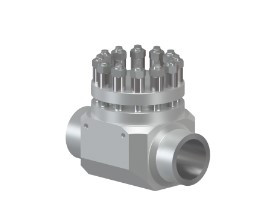

Armatury AS33 Gate Valve

BRAND : Armatury

Application The gate valve is designed to open or close the

service fl uid fl ow fully. The gate valve is not used for fl ow-control or

throttling purposes. It is used in primary, secondary and auxiliary circuits of

the nuclear power plants outside hermetically sealed zones. Working medium

water steam air gas other fl uids Maximum working temperature Tmax 250 °C

Technical description The gate valves designed in cast version are with rising

stem and fl exible wedge. The gate valve is made of cast semi-fi nished

products. The body and the bonnet are connected mutually by fl anged

joint–bolted design. The seat rings are welded into the body. The sealing

surfaces of the seats and of the wedge are overlay by hard faced but without

cobalt overlay alloy. The packing is made of graphite rings. The gate valves

designed in fully welded version are fl at with rising stem and solid wedge.

The body and the bonnet are fabricated and connected together by fl anged

joint. Production range cast version - DN 50-800 MAWP up to 4,0 Mpa fully

welded version - DN 400-1200 MAWP up to 1,0 Mpa

Details

Application The gate valve is designed to open or close the

service fl uid fl ow fully. The gate valve is not used for fl ow-control or

throttling purposes. It is used in primary, secondary and auxiliary circuits of

the nuclear power plants outside hermetically sealed zones. Working medium

water steam air gas other fl uids Maximum working temperature Tmax 250 °C

Technical description The gate valves designed in cast version are with rising

stem and fl exible wedge. The gate valve is made of cast semi-fi nished

products. The body and the bonnet are connected mutually by fl anged

joint–bolted design. The seat rings are welded into the body. The sealing

surfaces of the seats and of the wedge are overlay by hard faced but without

cobalt overlay alloy. The packing is made of graphite rings. The gate valves

designed in fully welded version are fl at with rising stem and solid wedge.

The body and the bonnet are fabricated and connected together by fl anged

joint. Production range cast version - DN 50-800 MAWP up to 4,0 Mpa fully

welded version - DN 400-1200 MAWP up to 1,0 Mpa