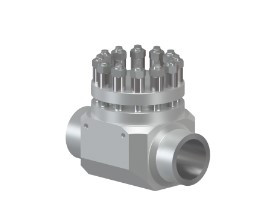

Armatury S43.1 acc. To ASME Gate Valve

BRAND : Armatury

Application Gate valves are isolating valves designed for

full closing or opening of working media flow. If the gate valves are used for

regulating or throttling purposes, the manufacturer does not guarantee

tightness of the gate valves. For regulation we recommend to use special

control gate valve type S33.C. Working medium water non-corrosive liquids steam

air gases of group 1 and 2 petroleum and petroleum products The service fluids

shall not contain rough impurities. Technical description The gate valve is an

outside-screw-and-yoke, full bore with flexible wedge and rising stem. The body

and the bonnet are made of castings and are connected by a flanged joint.

The seating surfaces of the seats and the wedge are made in compliance with API

600. The seat rings are welded into the body. The gate valves are equipped with

a back seat. The gate valves are a bi-directional sealing valves. The

body-bonnet joint and the packing chamber are sealed with asbestos-free gasket

and packing which guarantee a long life service. The requirement for an

automatic body cavity pressure relief shall be specified in the purchase order.

Pressure relief can be achieved by: drilling a hole through one disc of

the wedge, special valve incorporated into the wedge, external bypass, use of

solid wedge. TA-Luft design on request.

Details

Application Gate valves are isolating valves designed for

full closing or opening of working media flow. If the gate valves are used for

regulating or throttling purposes, the manufacturer does not guarantee

tightness of the gate valves. For regulation we recommend to use special

control gate valve type S33.C. Working medium water non-corrosive liquids steam

air gases of group 1 and 2 petroleum and petroleum products The service fluids

shall not contain rough impurities. Technical description The gate valve is an

outside-screw-and-yoke, full bore with flexible wedge and rising stem. The body

and the bonnet are made of castings and are connected by a flanged joint.

The seating surfaces of the seats and the wedge are made in compliance with API

600. The seat rings are welded into the body. The gate valves are equipped with

a back seat. The gate valves are a bi-directional sealing valves. The

body-bonnet joint and the packing chamber are sealed with asbestos-free gasket

and packing which guarantee a long life service. The requirement for an

automatic body cavity pressure relief shall be specified in the purchase order.

Pressure relief can be achieved by: drilling a hole through one disc of

the wedge, special valve incorporated into the wedge, external bypass, use of

solid wedge. TA-Luft design on request.