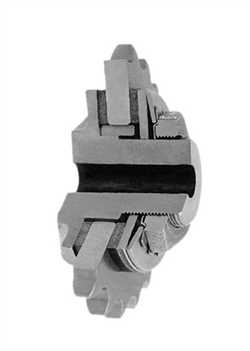

WARNER ELECTRIC Encapsulated Coils

BRAND : WARNER ELECTRIC

To protect your coil assembly from moisture, corrosive chemicals, vibration and other hard working conditions, any Warner Electric freestanding or bobbin wound coil can be encapsulated with tough and high temperature resistant thermoplastics.

Additional advantages of this superior protection include improved insulation properties and dielectric strength plus maximum structural integrity and impact resistance in all environments. For many applications, reduced assembly operations are also made possible by encapsulating the coil in a unitized package complete with structural components.

Retractable pin mold technology enables Warner Electric to provide waterproof (IP-65 and IP-69) overmolded coil assemblies.

Details

To protect your coil assembly from moisture, corrosive chemicals, vibration and other hard working conditions, any Warner Electric freestanding or bobbin wound coil can be encapsulated with tough and high temperature resistant thermoplastics.

Additional advantages of this superior protection include improved insulation properties and dielectric strength plus maximum structural integrity and impact resistance in all environments. For many applications, reduced assembly operations are also made possible by encapsulating the coil in a unitized package complete with structural components.

Retractable pin mold technology enables Warner Electric to provide waterproof (IP-65 and IP-69) overmolded coil assemblies.