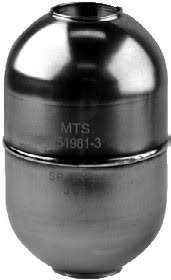

Mts Sensor MHRM Mobile Hydraulic Position Sensor

BRAND : Mts Sensor

Output

Signal characteristic Analog output restricted by noise or A/D converter of control unit

Voltage 0.25…4.75 VDC; 0.5…4.5 VDC; 0.25…9.75 VDC; 4.75…0.25 VDC; 4.5…0.5 VDC; 9.75…0.25 VDC

Current 4…20 mA; 20…4 mA

Measured value Position

Measurement parameters

Resolution ±0.1 mm typical

Linearity 0050…0250 mm 0255…2000 mm 2005…2500 mm

? ±0.1 mm ±0.04 % (F.S.) ? ±0.8 mm

Hysteresis ? ±0.2 mm

Setpoint tolerance ±2 mm

Operating conditions

Operating temperature ?40…+105 °C

Storage temperature ?25…+65 °C

Humidity 90 % relative humidity, no condensation

Ingress protection – M12 connector IP67 / IP69K (correctly fitted)

Ingress protection – Sensor housing IP67

Shock test (according to EN 50155) According to EN 61373 Cat2 (Bogie) and Cat3 (Axle)

Vibration test (according to EN 50155) According to IEC 60068-2-64-Fn Cat3 (Axle)

EMC test (according to EN 50155) EN 50121-3-2

ISO 14982 Agricultural and forest machines

EN 13309 Construction machines

ISO 16750-2

Electromagnetic immunity according to EN 61000-6-2

Electromagnetic emission according to EN 61000-6-3

RF immunity 200 V/m per ISO 11452-2/-4

PCB coating According to EN 50155

Pressure (according to DIN EN ISO 19879)* Ø 7 mm sensor rod Ø 10 mm sensor rod

PN (nominal operating) 300 bar 350 bar

Pmax (max. overload) 400 bar 450 bar

Pstatic (proof pressure...

Details

Output

Signal characteristic Analog output restricted by noise or A/D converter of control unit

Voltage 0.25…4.75 VDC; 0.5…4.5 VDC; 0.25…9.75 VDC; 4.75…0.25 VDC; 4.5…0.5 VDC; 9.75…0.25 VDC

Current 4…20 mA; 20…4 mA

Measured value Position

Measurement parameters

Resolution ±0.1 mm typical

Linearity 0050…0250 mm 0255…2000 mm 2005…2500 mm

? ±0.1 mm ±0.04 % (F.S.) ? ±0.8 mm

Hysteresis ? ±0.2 mm

Setpoint tolerance ±2 mm

Operating conditions

Operating temperature ?40…+105 °C

Storage temperature ?25…+65 °C

Humidity 90 % relative humidity, no condensation

Ingress protection – M12 connector IP67 / IP69K (correctly fitted)

Ingress protection – Sensor housing IP67

Shock test (according to EN 50155) According to EN 61373 Cat2 (Bogie) and Cat3 (Axle)

Vibration test (according to EN 50155) According to IEC 60068-2-64-Fn Cat3 (Axle)

EMC test (according to EN 50155) EN 50121-3-2

ISO 14982 Agricultural and forest machines

EN 13309 Construction machines

ISO 16750-2

Electromagnetic immunity according to EN 61000-6-2

Electromagnetic emission according to EN 61000-6-3

RF immunity 200 V/m per ISO 11452-2/-4

PCB coating According to EN 50155

Pressure (according to DIN EN ISO 19879)* Ø 7 mm sensor rod Ø 10 mm sensor rod

PN (nominal operating) 300 bar 350 bar

Pmax (max. overload) 400 bar 450 bar

Pstatic (proof pressure) 525 bar 625 bar

Design / Material

Housing lid Compound PBT (glass fiber reinforced plastic); sealing ring: TPU

Sealing O-ring NBR with back-up ring PTFE

Sensor electronics housing Stainless steel 1.4305 (AISI 303)

Sensor rod – Ø 7 mm Stainless steel 1.4301 (AISI 304)

Sensor rod – Ø 10 mm Stainless steel 1.4306 (AISI 304L)

Stroke length 50…2500 mm

Mechanical mounting

Mounting instruction Please consult the technical drawings

Mounting position Any

Electrical installation

Connector InterConnection plug

Operating voltage 12 / 24 VDC (8…32 VDC)

24 VDC supply 12 VDC supply

Load (output mA) RL

? 500 ? RL

? 250 ?

Load (output VDC) RL

? 10 k? RL

? 10 k?

Inrush current 4.5 A / 2 ms 2.5 A / 2 ms

Operating voltage ripple 1 %PP

Power drain ? 1 W

Over voltage protection (VDC-GND) Up to +36 VDC

Polarity protection (GND-VDC) Up to ?36 VDC

Insulation resistance R ? 10 M? @ 60 sec according to EN 50155

Dielectric strength 708 VDC (DC ground to machine ground) according to EN 50155

MHRM EMBEDDED – TECHNICAL DATA

*/ According to calculations under use of the FKM guideline

Cycles Ø 7 mm sensor rod Ø 10 mm sensor rod

Dynamic pressure: < 2 × 106

pressure cycles 300 bar 350 bar

Static pressure: < 2 × 104A

pressure cycles 400 bar 450 bar

Proof pressure: Maximum 5 minutes testing time for cylinder pressure test 525 bar 625 bar