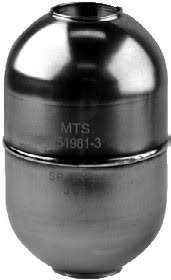

Mts Sensor MH SIL2 Mobile Hydraulic Position Sensor

BRAND : Mts Sensor

Output

Signal characteristic Continuously analog output restricted by noise or A/D converter of control unit

Voltage 0.5…4.5 VDC with failure signal < 0.5 VDC LO > 4.5 VDC HI

Current 4…20 mA with failure signal < 4.0 mA LO > 20 mA HI

Measured value Position

Measurement parameters

Resolution Typ. 0.1 mm

Power uptime Typ. 250 ms

Linearity 0050…0250 mm 0255…2000 mm 2005…2500 mm

? ±0.1 mm ±0.04 % (F.S.) ? ±0.8 mm

Hysteresis ±0.1 mm

Internal sample rate 1 ms

Setpoint tolerance ? 1 mm

Operating conditions

Operating temperature electronics ?40…+100 °C

Storage temperature ?20…+65 °C

Fluid temperature ?30…+85 °C

Humidity EN 60068-2-30, 90 % rel. humidity, no condensation

Ingress protection – M12 connector EN 60529 – IP69K (correctly fitted)

Ingress protection – Sensor housing EN 60529 – IP67

Shock test IEC 60068-2-27, 100 g (6 ms) single shock, 50 g (11 ms) at 1000 shocks per axis

Vibration test IEC 60068-2-64, 20 g (r.m.s.) Ø 10 mm pressure pipe (10…2000 Hz) – resonance frequencies excluded

EMC test UNECE Regulation 10 Rev 5: Electromagnetic Compatibility

ISO 14982 Agricultural and forest machines

EN 13309 Construction machines

Immunity: ISO 11452-2 (200 V/m Antenna), ISO 11452-4 (200 mA BCI)

Emissions: CISPR 25

Transiente Impulses: ISO 7637-1/2

E.S.D.: ISO/TR 10605

The sensor meets the requirem...

Details

Output

Signal characteristic Continuously analog output restricted by noise or A/D converter of control unit

Voltage 0.5…4.5 VDC with failure signal < 0.5 VDC LO > 4.5 VDC HI

Current 4…20 mA with failure signal < 4.0 mA LO > 20 mA HI

Measured value Position

Measurement parameters

Resolution Typ. 0.1 mm

Power uptime Typ. 250 ms

Linearity 0050…0250 mm 0255…2000 mm 2005…2500 mm

? ±0.1 mm ±0.04 % (F.S.) ? ±0.8 mm

Hysteresis ±0.1 mm

Internal sample rate 1 ms

Setpoint tolerance ? 1 mm

Operating conditions

Operating temperature electronics ?40…+100 °C

Storage temperature ?20…+65 °C

Fluid temperature ?30…+85 °C

Humidity EN 60068-2-30, 90 % rel. humidity, no condensation

Ingress protection – M12 connector EN 60529 – IP69K (correctly fitted)

Ingress protection – Sensor housing EN 60529 – IP67

Shock test IEC 60068-2-27, 100 g (6 ms) single shock, 50 g (11 ms) at 1000 shocks per axis

Vibration test IEC 60068-2-64, 20 g (r.m.s.) Ø 10 mm pressure pipe (10…2000 Hz) – resonance frequencies excluded

EMC test UNECE Regulation 10 Rev 5: Electromagnetic Compatibility

ISO 14982 Agricultural and forest machines

EN 13309 Construction machines

Immunity: ISO 11452-2 (200 V/m Antenna), ISO 11452-4 (200 mA BCI)

Emissions: CISPR 25

Transiente Impulses: ISO 7637-1/2

E.S.D.: ISO/TR 10605

The sensor meets the requirements of the EC directives and is marked with

Pressure (according to DIN EN ISO 19879)* Ø 10 mm pressure pipe

PN (nominal operating) 350 bar

Pmax (max. overload) 450 bar

Pstatic (proof pressure) 625 bar

Design / Material

Sensor electronics housing Stainless steel 1.4305 (AISI 303)

Sealing O-ring 40.87 × 3.53 mm NBR 80, back-up ring 42.6 × 48 × 1.4 PTFE

Sensor rod Stainless steel 1.4306 (AISI 304L)

M12 connector insert Material: polyamide reinforces; O-ring 7 × 1.35 mm NBR 70; pins: brass with gold plated pins

M12 flange Brass nickel-plated with O-ring 13 × 1.6 NBR 70

Stroke length 50…2500 mm

Mechanical mounting

Mounting position Any

Mounting instruction Please consult the technical drawings

Electrical installation

Connector M12 male connector

Supply voltage 12 VDC (8…32 VDC) 24 VDC (16…32 VDC)

Current consumption Typ. < 100 mA Typ. < 50 mA

Load (output VDC) RL

> 10 k? RL > 10 k?

Load current (output VDC) Typ. 0.5 mA Typ. 0.5 mA

Load (output mA) RL

< 250 ? RL

< 500 ?

Inrush current Max. 2.5 A/2 ms Max. 4.5 A / 2 ms

Supply voltage ripple < 1 % PP

Power drain < 1 W

Over voltage protection (GND - VDC) Up to +36 VDC

Polarity protection (GND - VDC) Up to ?36 VDC

Insulation Resistance R ? 10 M? @ 60 sec

Electric strength 500 VDC (DC GND to chassis GND)

*/ According to calculations under use of the FKM guideline

Cycles Ø 10 mm sensor rod

Dynamic pressure: < 2 × 106

pressure cycles 350 bar

Static pressure: < 2 × 104

pressure cycles 450 bar

Proof pressure: Maximum 5 minutes testing time for cylinder pressure test 625 bar