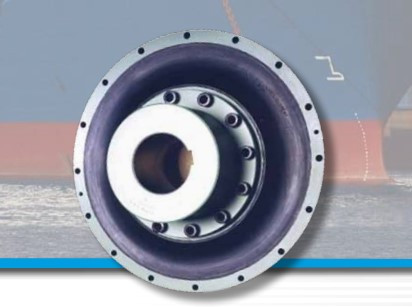

KWD ELKU-N A 40 - 60 H7P1 (x100) - 50 H7P1 (x100)KWN 22013 Coupling

BRAND : KWD

technical features

The flexible claw coupling N (ELKU-N) is a positive-locking, torsionally

flexible coupling which allows radial, axial and angular

displacement between the driving and the driven shafts. It is a

fail-safe coupling.

The torque will be transmitted by the flexible buffer set fitted in the

buffer part and distributed symmetrical arround the circumference

of the coupling.

The claws of the claw ring(type A) or claw part (type B) are operating

in the space between the buffers.

The buffers are subjected to compression. That`s why there´s a

low wear and high loading capacity.

The high damping of the coupling protects the drive from excessive

dynamic overloading. The progressively rising spring charcteristic

allows a rapid reduction of energy oscillations and limits their

amplitude.

Perfect operation can be guaranteed at a working temperature of

- 30 °C to + 80 °C.

The standard hub material is grey cast iron

EN-GJL-250-DIN EN 1561.1561.

Details

technical features

The flexible claw coupling N (ELKU-N) is a positive-locking, torsionally

flexible coupling which allows radial, axial and angular

displacement between the driving and the driven shafts. It is a

fail-safe coupling.

The torque will be transmitted by the flexible buffer set fitted in the

buffer part and distributed symmetrical arround the circumference

of the coupling.

The claws of the claw ring(type A) or claw part (type B) are operating

in the space between the buffers.

The buffers are subjected to compression. That`s why there´s a

low wear and high loading capacity.

The high damping of the coupling protects the drive from excessive

dynamic overloading. The progressively rising spring charcteristic

allows a rapid reduction of energy oscillations and limits their

amplitude.

Perfect operation can be guaranteed at a working temperature of

- 30 °C to + 80 °C.

The standard hub material is grey cast iron

EN-GJL-250-DIN EN 1561.1561.