Details

Internationally recognized as the most trusted name in fluid film bearings, Kingsbury brings its engineering leadership to Coleherne, a European manufacturer established over 110 years ago. The fruit of our longstanding collaborative efforts is the crowning achievement of technical innovation that we call the KingCole bearing.

KingCole incorporates Kingsbury's efficient Leading Edge Groove (LEG) lubrication system with a non-equalized thrust bearing often used in Europe. The LEG system lowers frictional losses and lube oil requirements with an accompanying reduction in oil film temperatures – features that contribute to overall installation economy.

Important design features, such as Kingsbury's spherical pad pivot as well as conservative load ratings, allow you to confidently specify the KingCole in even the toughest applications.

Perfect for retrofit, the KingCole can be specified for one-to-one replacement in existing applications, reducing downtime and ensuring an exact fit. ISO standards are used for all dimensional tolerances.

A true manufacturing and service alliance, KingCole is assembled and shipped from Coleherne's UK facility near Manchester, England. Engineering assistance can be obtained from either Kingsbury or Coleherne and site services originate directly from England.

The Advantages of LEG Technology

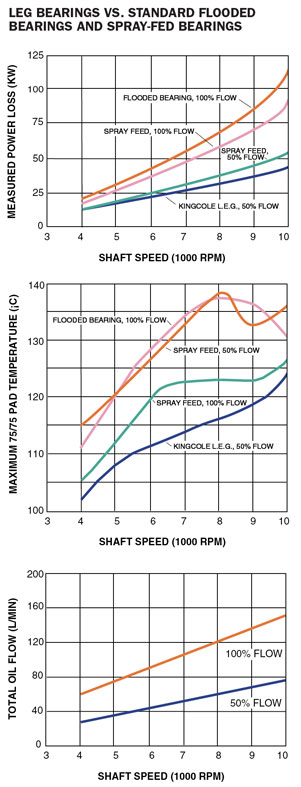

Leading Edge Groove (LEG) technology, introduced by Kingsbury in 1984, has revolutionized the world of fluid-film bearings. LEG lubrication has made it possible for the world's leading equipment manufacturers to simultaneously increase bearing capacity, reduce friction losses and hold white metal temperatures within acceptable limits. When compared to a standard thrust bearing, the advanced design KingCole LEG bearing can:

- Reduce operating temperatures at the 75/75 location by 8° to 27° C, depending on shaft speed.

- Provide a load carrying capacity increase of 15-20%, based on that temperature reduction.

- Operate at oil flow rates as much as 60% lower, with an accompanying reduction in friction losses of 40%.

General Description

While the general design arrangement of the KingCole at first glance resembles other non-equalized bearings, certain key features help it outperform competitors’ tilting-pad bearings in use today.

Pads

All KingCole bearing pads feature Leading Edge Groove (LEG) lubrication grooves to improve oil flow, reduce power loss, friction and pad temperatures. Bearings are designed for a specific shaft direction of rotation, and the pad pivots are therefore offset to increase the load-carrying capacity. As there are no leveling plates, the pad heights are held to tighter tolerances to help assure better load distribution.

All KingCole bearing pads feature Leading Edge Groove (LEG) lubrication grooves to improve oil flow, reduce power loss, friction and pad temperatures. Bearings are designed for a specific shaft direction of rotation, and the pad pivots are therefore offset to increase the load-carrying capacity. As there are no leveling plates, the pad heights are held to tighter tolerances to help assure better load distribution.

Standard materials of construction of the pad body are low carbon steel with a high tin content white metal face, although alternative materials are possible for unusual applications.

KingCole pads have a distinctive raised "button" on the back to allow it to tilt in all directions, unlike the more familiar rocking strip that allows the pad to tilt only from side to side. Pad buttons are made of carbon tool steel, heated to 52 to 57 Rockwell C to prevent flattening of the sphere. Kingsbury tests indicate that this feature significantly lowers the spread of temperatures from pad to pad.

Carrier Rings

The carrier rings, typically manufactured by Coleherne, are designed to exacting ISO tolerances and are normally split to allow simple installation in tough-to-reach applications.  Standard material of construction is low carbon steel with a tensile strength of 483 MPa. Lubrication ports in the carrier ring provide oil directly to the bearing pads, ensuring even pressure and distribution of the oil.

Standard material of construction is low carbon steel with a tensile strength of 483 MPa. Lubrication ports in the carrier ring provide oil directly to the bearing pads, ensuring even pressure and distribution of the oil.

Pad Retention

Pads are held in place by a retaining fastener, and both can be easily removed to facilitate service or replacement.

Oil Feed Tube

The oil feed tube, connecting the base ring and pad, is designed so that the pad is free to pivot. This not only allows freedom of movement in the pad, but also eliminates the possibility of leakage by directing the oil directly to the pad face.

LEG Bearing Housing Requirements

KingCole's unique split-ring design makes installation easier than standard bearings. |

The bearing housing requirements for the KingCole LEG bearing are similar to those of standard thrust bearings. Oil seals at the back of the carrier rings are not required as the inlet oil is confined to passages within the base ring assembly. Fresh oil enters the bearing through an annulus located in the back of the base ring. The discharge space should be large enough to minimize contact between the discharged oil and the rotating collar. The discharge oil outlet should be amply sized so that oil can flow freely from the bearing cavity.

We recommend a discharge opening, equal in diameter to 80% of the recommended collar thickness. If possible, the discharge outlet should be located in the bottom of the bearing housing. Alternately, it should be located tangential to collar rotation.

LEG — Designed to Outperform Flooded and Spray Feed Bearing Technology

The KingCole's LEG bearing design has proven itself through exhaustive testing and field research to represent the ultimate in directed lubrication technology. Yet the design concept is remarkably – and elegantly – simple.

The bearing shoes and aligning ring are constructed so that cool inlet oil flows from the leading edge groove directly into the oil film. The cool oil in the oil film wedge insulates the babbitt face from the hot oil carried over by the rotating collar.

Unlike the KingCole LEG bearing, spray-fed bearings introduce the lubricant between the bearing surfaces, not directly onto them. This can result in uneven bearing lubrication and the need to supply impractically high pressure to effectively scour off the hot oil adhering to the thrust collar.

Friction power loss is lower than both flooded and spray feed bearings due to the reduced oil flow. The flow of cool oil over the leading edge lowers pad surface temperatures, increasing the KingCole's capacity.

The resulting performance improvements are shown in these graphs.