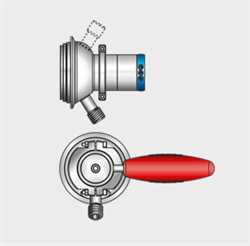

Kieselmann 4366 S-S Leakage Butterfly Valve

BRAND : Kieselmann

Compact and cost-effective

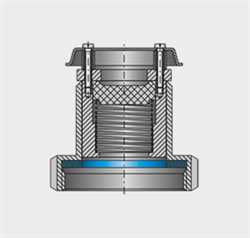

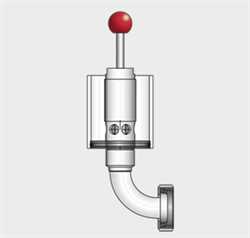

KIESELMANN leakage butterfly valves are the cost-effective and space-saving solution for safe product separation in process plants. They are used as reliable shut-off devices on panels and containers. In contamination-sensitive areas, you can offer extra security. A leak caused by seal wear can be detected and corrected immediately.

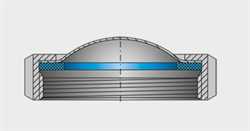

KIESELMANN leakage butterfly valves are generally available in intermediate flange version. This construction and the split housing allow the seals to be easily and quickly replaced.

Modular for individual solutions

Details

Compact and cost-effective

KIESELMANN leakage butterfly valves are the cost-effective and space-saving solution for safe product separation in process plants. They are used as reliable shut-off devices on panels and containers. In contamination-sensitive areas, you can offer extra security. A leak caused by seal wear can be detected and corrected immediately.

KIESELMANN leakage butterfly valves are generally available in intermediate flange version. This construction and the split housing allow the seals to be easily and quickly replaced.

Modular for individual solutions

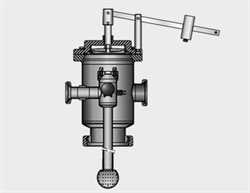

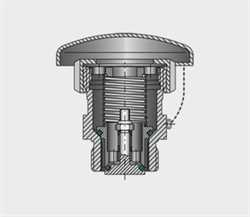

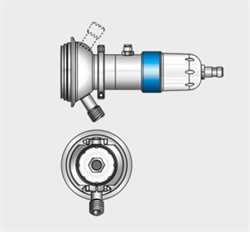

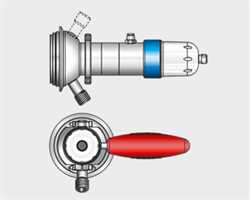

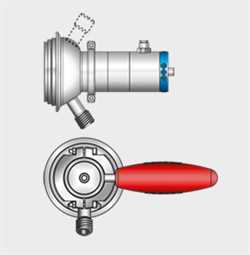

Of course, you do not have to do without automation in this cost-effective leak-proof valve sector. Our modular system makes it possible to change over quickly and easily from manual to pneumatic drive without removing the valves from the piping system. The drives are available with sensors or control head KI-TOP. KIESELMANN pneumatic rotary actuators are characterised by a particularly high torque. The closed version in stainless steel housing is completely maintenance-free. We give you a 5-year guarantee. The standard position indicator lets you know at any time how the valve is switched. The practical end position detector ensures permanently reliable feedback without the hassle of readjusting the limit switches. Our pneumatically driven leakage butterfly valves can be equipped with sensors or KI-Top control heads.

• Easy to install

• Cost-effective leakage protection

• Hygienically safe due to easy cleaning of the leakage chamber

• Simple and compact design

• Maintenance-friendly construction with intermediate flange design and only one sealing element

• Fully automatable PLC or ASI bus

• Ergonomic thermal protection handle (optionally in colour of choice)

• Drives selectable, three power levels

• Sealing materials EPDM, HNBR

Technical data

Sizes:

DN 50–150, 2"–4"

Seals:

EPDM HNBR SIP 140°C, 30 min

SIP 100°C, 30 min

Product-contacting surfaces :

Ra ? 0.8 µm e-polished

Materials:

in product contact 1.4404 / AISI 316L

Actuator:

PDA 75 / PDA 100 / PDA 125

Operating pressure:

DN 50–100 / 2"–4" max. 10 bar max. 6

DN 125 DN 150 bar max. 4 bar

Control air:

5.5–8 bar lower control air pressures on request

Operating temperature:

95 °C