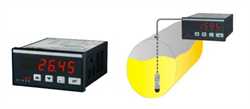

Hengesbach DTA 9648 Digital tank level display

BRAND : Hengesbach

Features

- suitable for measuring the content of tanks, in particular pressurised tanks, by determining a pressure difference

- 2 inputs 0/4...20 ma or 0/2...10 v dc for pressure transmitter

- 1 input for automatic filling level correction

- volume or mass display (weight)

- 6 standard as well as any special tank shapes selectable

- max. 4 alarm outputs, change-over relay or transistor

- galvanically isolated analogue outputs, 0/4...20 ma, 0/2...10 v dc (load-dependent)

- protection type in front ip 65

- display scope digits 0...999999

- adjustment in pressure-free state possible

Details

Features

- suitable for measuring the content of tanks, in particular pressurised tanks, by determining a pressure difference

- 2 inputs 0/4...20 ma or 0/2...10 v dc for pressure transmitter

- 1 input for automatic filling level correction

- volume or mass display (weight)

- 6 standard as well as any special tank shapes selectable

- max. 4 alarm outputs, change-over relay or transistor

- galvanically isolated analogue outputs, 0/4...20 ma, 0/2...10 v dc (load-dependent)

- protection type in front ip 65

- display scope digits 0...999999

- adjustment in pressure-free state possible

Description

The DTA 9648 tank content display was designed for all applications in the tank content measurement area and is, in particular, used for volume measurements with liquid media in tanks of various shapes. A connection for a pressure transmitter with an analogue output 0/4...20 mA or 0/2...10 V DC is available, as well as a 2nd measuring input for filling level measurements using differential pressure.

The volume calculations are based on measuring the hydrostatic pressure when the density of the medium is known. The filling level is calculated and displayed by using the tank geometry - the formuli for the most common tank shapes are internally stored and can be called up - or a sampling point table than is created by volumetric calibration.

The device provides the option of connecting an additional level sensor. When a specific level has been reached, thedisplay is corrected to the value that corresponds to the filling height in the tank in which the level sensor is installed. Programming is performed at the membrane keyboard in front. The alarm outputs can be programmed as min. or max. functions. The switching states are indicated by LEDs. When the digital filter is activated, the mean of 16 measuring values is continuously calculated and displayed. A galvanically isolated analogue signal in the range 0...20 mA / 0...10 V DC or 4...20 mA / 2...10 V DC that is proportional to the tank content, is provided. Switching from a current to a voltage signal is load-dependent (> 500 ? to voltage