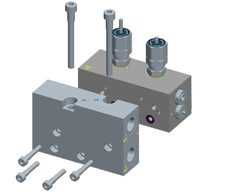

Dropsa SMX-3-V 08S-04BB-04S Distributor

BRAND : Dropsa

MODULAR CONCEPT

The modularity of the SMX progressive dividers allows for extremely easy flexibility in adapting to the lubrication system to suit the

need of the design of the system.

COMPATIBILITY WITH DROPSA PROGRESSIVE SYSTEMS

The compatibility of the AIR/OIL. block with traditional SMX

systems allows one or more AIR/OIL blocks to be inserted

into systems that are already in operation: it’s only necessary

to have a compressed air generator.

SAVE ON LUBRICANT

The oil delivered into air stream is accurately metered

according to the effective requirement of the lubrication

point. This avoids expensive lubricant wastage.

LUBRICANT VISCOSITY

It is possible to use any type of lubricant with viscosity

between 15 e 1000 cSt at a fluids working temperature

between 0°C e 80°C: The best conditions are obtained with oil

viscosity between 32 e 320 cSt at a temperature 40°C:

COOLING OF LUBRICATED PARTS

The continuous supply of a mixed air stream, besides

lubricating, also has a cooling effect.

RETAINING ACTION

The over pressure inside the lubricated element prevents the

ingress of foreign bodies.

CONTROL FUNCTION

Thanks to the progressive system, the malfunctioning of a

metering element is signaled by a control device.

ENVIRONMENT FRIENDLY

The Air/Oil system does not produce oil mist.

Details

MODULAR CONCEPT

The modularity of the SMX progressive dividers allows for extremely easy flexibility in adapting to the lubrication system to suit the

need of the design of the system.

COMPATIBILITY WITH DROPSA PROGRESSIVE SYSTEMS

The compatibility of the AIR/OIL. block with traditional SMX

systems allows one or more AIR/OIL blocks to be inserted

into systems that are already in operation: it’s only necessary

to have a compressed air generator.

SAVE ON LUBRICANT

The oil delivered into air stream is accurately metered

according to the effective requirement of the lubrication

point. This avoids expensive lubricant wastage.

LUBRICANT VISCOSITY

It is possible to use any type of lubricant with viscosity

between 15 e 1000 cSt at a fluids working temperature

between 0°C e 80°C: The best conditions are obtained with oil

viscosity between 32 e 320 cSt at a temperature 40°C:

COOLING OF LUBRICATED PARTS

The continuous supply of a mixed air stream, besides

lubricating, also has a cooling effect.

RETAINING ACTION

The over pressure inside the lubricated element prevents the

ingress of foreign bodies.

CONTROL FUNCTION

Thanks to the progressive system, the malfunctioning of a

metering element is signaled by a control device.

ENVIRONMENT FRIENDLY

The Air/Oil system does not produce oil mist.