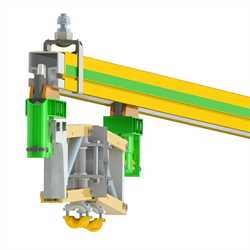

Conductix Wampfler BestaPower A180 Compressed Air and Electric Supply Systems

BRAND : Conductix Wampfler

The A180 aluminum profile with integral compressed air supply and high load reduces the need of the steel structure.

Its compatibility with the A62 profile, grooves on three sides that allow the installation of energy supply and peripheral equipment, as well as the option for stationary air supply using tapping valves and tapping carriages, or continuous energy supply with a laterally suspended energy guiding chain, all this characterizes A180 as the peak performer among the Bestapower profiles.

Special features

- Ideal compressed air supply over the entire length of the rail profile using tapping valves

- Low installation effort due to long suspension distance

- Compressed air supply via tapping valves: no cable / hose loops or chain channel for energy guidin...

Details

The A180 aluminum profile with integral compressed air supply and high load reduces the need of the steel structure.

Its compatibility with the A62 profile, grooves on three sides that allow the installation of energy supply and peripheral equipment, as well as the option for stationary air supply using tapping valves and tapping carriages, or continuous energy supply with a laterally suspended energy guiding chain, all this characterizes A180 as the peak performer among the Bestapower profiles.

Special features

- Ideal compressed air supply over the entire length of the rail profile using tapping valves

- Low installation effort due to long suspension distance

- Compressed air supply via tapping valves: no cable / hose loops or chain channel for energy guiding chain

- Simple installation of peripheral equipment and power supply using profile grooves

- Optimum compressed air supply even with multiple loads and high air consumption due to integral compressed air pipe

- Minimal planning effort and high degree of system flexibility due to modular design.

- Application-specific solutions adapted to customer needs with energy supply using tapping valves, connection plates, or an energy guiding chain

- Above-average lifetime due to screw connector system – reusability of all components while adapting to changed production sequences

- Flexible workplace layout with equipment carriers / tool transporters with energy supply

- Reliable, accurate guiding with extruded aluminum profile

- Reduced energy costs using optimized tapping valve system

Main applications

- Long production and assembly lines in the automotive industry, utility vehicle construction and agricultural technology

Standard application data

- Maximum intrinsic weight of rails [kg/m]: 5,7

- Maximum suspension distance [m]: 6

- Maximum point load [kg]: 120

- Maximum segment load [kg/m]: 10 at 6 m suspension distance

- Maximum travel speed [m/min] manual pushing

- Cycle length tapping valve system [m]: arbitrary

- Maximum cycle length with energy guiding chain [m]: 18

- Standard spacing between tapping valves/compressed air taps: [m]: 1,5

- Maximum operating pressure [bar]: 10

- Interfaces: G1 ¼" ball valve at start of system | tapping carriage with ½“ hose or G ½“ connections along the profile

- Compressed air supply through tapping valves and tapping carriage G 3/8“ or G ½"

- Operating conditions indoors [°C]: +5 to +60