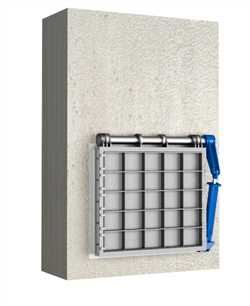

CMO Serie PL Damper

BRAND : CMO

Product description

The louver damper is composed of various blades which each turn on the central shaft. The ends are joined to the pipes via flanges. Normally, the louver ...

Details

Product description

The louver damper is composed of various blades which each turn on the central shaft. The ends are joined to the pipes via flanges. Normally, the louver damper is supplied as one piece, except in those applications in which the dimensions of the equipment require special transport.

Construction

The body of the PL damper is machine welded and can be made of different materials. The standard construction sizes range from 150×150 mm (minimum) to 3000×3000 mm although larger sizes are available on request. The blades are made flat, with reinforcing ribs and are supported on two semi?shafts. The flat blade system is sufficiently rigid for the working pressures of these valves and they do not produce significant load losses.

Utilization

The PL dampers have two types of seals. Depending on the application you can choose between: Swing?thru (97% seal), for environments with high dust concentrations, the metal/metal seal (99% seal) and the step?seat joint for other applications that require greater watertight integrity, reaching 100% with air chamber sealing.

Sizes

Working pressures

Directives

• Pressure Equipment Directive:

(PED) ART 4.3 /CAT.1.

• Potential Explosive Atmospheres Directive:

(ATEX) CAT.3 ZONA 2 y 22 GD.