| Bespoke systems | Suits the customer’s application. Reduced design costs |

| Easy and compact installation | No power packs, piping, cylinders etc. Reduced HSE issues |

| Irreversible (static) | Maintains load position when power is off. Safety critical operation |

| Grease lubrication | Helps prevent leakage. Plant availability and HSE issues |

| Environmentally friendly | No hydraulic fluids to dispose of, or replace. Eliminates waste costs |

| Worm Technology | Quiet running. Noise reduction |

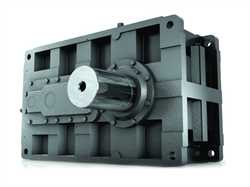

| Stainless steel execution | Suitable for severe environments. Reduced maintenance and through life costsProduct OptionsWorm Gear Screw JackOur mechanical Worm Gear Screw Jack with trapezoidal lifting screw available with translating lifting screw or lifting nut. - Can Lift up to a capacity of 1,000 kN (100 tonnes).

- A ball screw is available up to 500kN (50 tonne) and a roller screw is available on request

- Can run at a Lifting Speed of up to 5.4 m/min which is 90 millimeters per second.

- The majority of our worm gear screw jacks are self locking meaning enhanced safety and a cheaper solution.

Wide Screw Jack Range- Experienced application engineers will help guide you through your selection process helping you optimize your solution.

- We can make custom screwjacks for your extremely high load needs

- We will help you design the full linear drive system including all accessories such as bevel gearboxes, drive shafts, and sensors.

- Stainless Steel Screw Jacks available for challenging environments

|