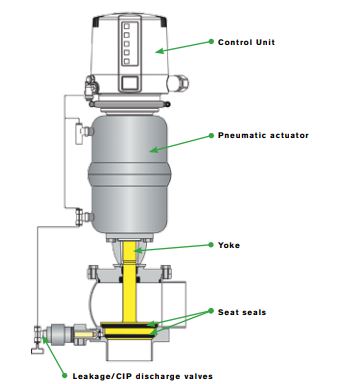

Apv SD4 Valve

BRAND : Apv

Safe Separation of Incompatible Media

With two serial seat seals and a separation cavity, the DELTA SD4 valves are designed for safe media separation.

Excellent Hygienic Features

DELTA SD4 valves have excellent hygienic characteristics due to a number of design features:

- Ball-shaped housing without sump or dome

Details

Safe Separation of Incompatible Media

With two serial seat seals and a separation cavity, the DELTA SD4 valves are designed for safe media separation.

Excellent Hygienic Features

DELTA SD4 valves have excellent hygienic characteristics due to a number of design features:

- Ball-shaped housing without sump or dome

- Crevice-free sealing

- Leakage discharge valves enabling drainage as well as cleaning of neutral cavity

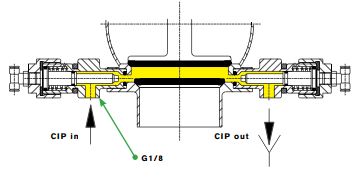

CIP/SIP Cleaning of Leakage Cavity

The DELTA SD4 valves have leakage discharge valves to drain the neutral area between the seals. The leakage discharge valves are used for supply and discharge of cleaning media, which enables CIP and SIP cleaning of the neutral area. Leakage valves and actuator are controlled by the same solenoid valve. Therefore, additional control is not required.

Multiple Designs Available, Incl. Aseptic

DELTA SD4 valves are available in a shut-off, a change-over and a tankoutlet design. Furthermore, the valves are available in an aseptic design with a supported flat TFM membrane.

Long Seal Life

Sealings designed with metallic stop ensure limited elastomer compression and, consequently, avoidance of sealing overstress. Moulded elastomer profile seals with clear identification markings ensure prompt and fail-safe identification of seals during maintenance

Maintenance-friendly

Only one hexagonal nut outside the product area ensures quick and easy service of the valve. Flanged valve body closure for safe and controlled disassembly and assembly of valve insert.

Theory of Operation

The DELTA SD4 valves are used for safe separation of incompatible media. Safe media separation is provided by a design with two seat seals. A ring-shaped leakage chamber is arranged between the two seals. It is forcible closed or opened to the atmosphere by the two leakage discharge valves.

In case of damage of the seat seals, the leakage will be drained via the leakage valves to the atmosphere and indicated.

Cleaning of the leakage chamber is undertaken via the leakage valves. The cleaning liquid is supplied via one leakage valve and discharged to the atmosphere via the second one. The directed flow of the cleaning liquid provides for a perfect cleaning of the whole leakage chamber.