Aoip LKS 1000 Leak Detection

BRAND : Aoip

Compressed air is a costly form of energy and 20 to 40% of it is lost through leaks.

Systematically checking for and eliminating leaks can therefore bring considerable energy savings.

Film, view and photograph the precise spot where compressed air, steam, pressurised gas and vacuums are leaking using the LEAKSHOOTER LKS1000 V.2.

No more need to spend hours with headphones on ears to try to locate leaks. As with infrared thermometry, check your network with LEAKSHOOTER:

- Embedde...

Details

Compressed air is a costly form of energy and 20 to 40% of it is lost through leaks.

Systematically checking for and eliminating leaks can therefore bring considerable energy savings.

Film, view and photograph the precise spot where compressed air, steam, pressurised gas and vacuums are leaking using the LEAKSHOOTER LKS1000 V.2.

No more need to spend hours with headphones on ears to try to locate leaks. As with infrared thermometry, check your network with LEAKSHOOTER:

- Embedded camera on reception cone

- Adjustable gain from 50 dB to 110 dB for use in any kind of surroundings

- Rechargeable Lithium-Ion battery with 5-6 hour operation time

- 40 kHz internal ultrasound sensor, frequency adjustable from 34 kHz to 46 kHz for smallest leaks

- Sound bandwidth of 2.5 kHz with stereo headphones

- User mode without camera (energy saving)

- Continuous measurement of dB, RMS and MAX, displayed on colour bargraph

- Dynamic real-time targeting showing the exact location of the ultrasonic source

- BMP pictures (1,000 to store), with USB connexion for upload on PC

Extremely sensitive, it is capable of finding all leaks, even the smallest, including those no bigger than the size of a syringe needle, at a distance of 15 metres. Leaks can be detected in all types of industrial environment thanks to the possibility of adjusting the gain on the device to filter out all undesirable noise.

|  |

|  |  |

| No leak | Near a small leakage | Face to a small leakage | Near a big leakage | Face to a big leakage |

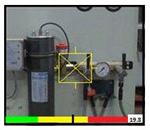

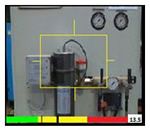

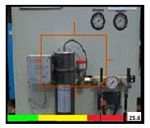

The LEAKSHOOTER LKS1000 V.2 is used like a camera. When it comes near a leak, a dynamic yellow target appears on the large colour screen. The target turns red and shrinks as it approaches the source of the leak. A bar graph at the bottom of the screen accompanies and facilitates the search.

When the device is facing the leak, a cross appears in the centre of the target. It is then possible to photograph and save the precise location of the leak.

For multiple industrial applications:

- Air leak

- Leakage of gas under pressure (oxygen, argon, nitrogen…)

- Vacuum leak (depressurized gas)

- Test of steam traps (optional accessory)

- Fault detection on bearings (optional accessory)

- Electrical default detection such as corona effect, partial discharges due to bad contacts, surface arc tracking caused by pollution…

- Sealing default detection (sound transparency) with ultrasound transmitter

Each photo is numbered, dated and timed and shows the dB RMS level of the leak.

The photos can be uploaded directly onto a PC via a USB cable (supplied), ready to be attached to inspection reports.

It is still possible, whilst visually searching for a leak, to use the traditional method of leak detection, listening for the hissing sound of the leak using the professional headphones also supplied, which can be plugged directly into the device.

Various accessories are available for the LEAKSHOOTER LKS1000 V.2 enabling it to be used for other applications as well as leak detection:

Detection in hard to reach areas with sensor :

Detection in hard to reach areas with sensor :

LKSFLEX, Flexible probe 400 mm long

LKSFLEX1500, Flexible probe 1500 mm long

For Steam trap control :

LKSPROBE, Mechanical US Sensor

Tightness and sealing control :

LKSDOME, Ultrasonic emitter with 13 emitters